Our Story

Founded in 2013, Tecglass is a renowned manufacturer of Flat Tempered Safety Glass (VST). With state-of-the-art equipment, it provides glasses for the following segments: automotive, civil construction, solar energy and many other applications in the industrial area. In addition to tempered glass, the company also produces all sets of doors and windows of the buses produced by Caio Induscar, as well as molded technical foams.

Tecglass has national and international approvals and a varied line of products that meet the most demanding standards in the market.

Its portfolio is made up of products prepared to meet projects with different dimensions and thicknesses.

Our Raw Material: Glass

Discovered more than 4,000 years ago, glass is composed of a blend of natural raw materials (silica, bark and limestone).A material that, due to its versatility and numerous application possibilities, is no longer a secondary element, and is no longer an option only for the aesthetic issue, gaining more and more space in the automotive sector, construction, architecture, design, among others.

In its applications, glass brings several benefits such as: allowing the entrance of natural light, interaction between the external and internal media, acoustic insulation and still adds energy saving.

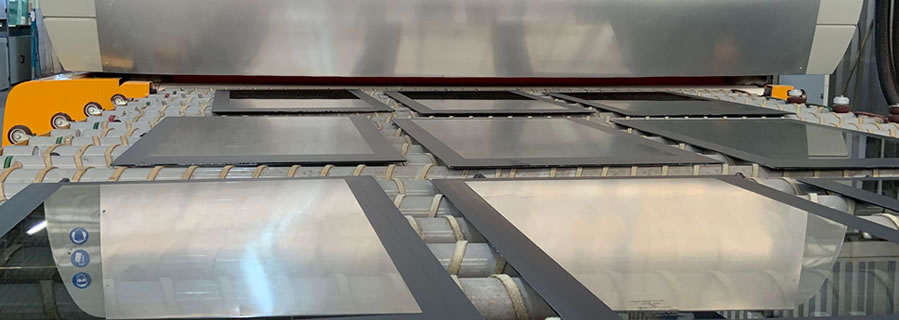

Procurement Process

Equipped with tempering ovens, Tecglass produces safety glass according to ABNT NBR 7199. After the tempering process, the glass retains its original appearance, becoming 4 to 5 times more resistant than a common.

The quenching process consists of subjecting the glass to a high temperature, between 600 ° and 700 ° Celsius. It is then abruptly cooled with air jets, causing a thermal shock, causing its molecules to contract and in this way, it becomes much more resilient and rigid.

Due to the modification process, if the tempered safety glass breaks, it will fragment into small pieces, considerably reducing the risk of accidents.